Progress update: Furniture, ageing and ATR-FTIR characterisation of industrial polymers

The objective of this work package is to create a set of representative polymer aged samples and a database of their infrared spectroscopy measurements.

For the provision of materials, neoprene and HDPE samples have been chosen and ordered for accelerated ageing test. A deformulation of each kind of unaged material and IR characterization of the initial state have been performed in order to get more information about the nature and content of different additives in these materials.

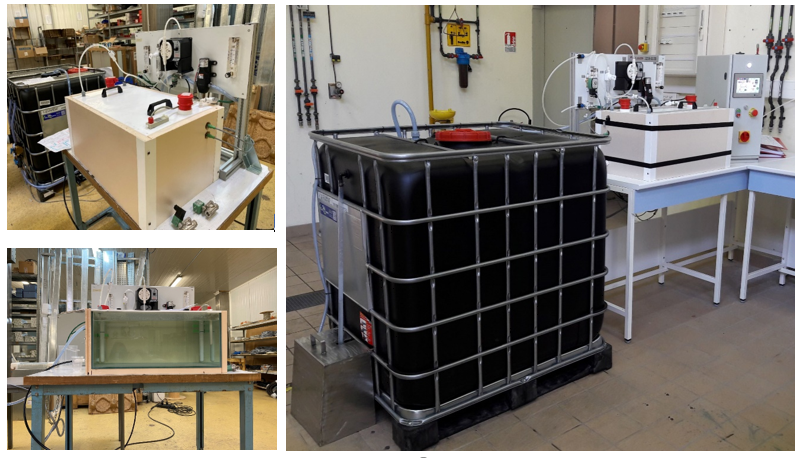

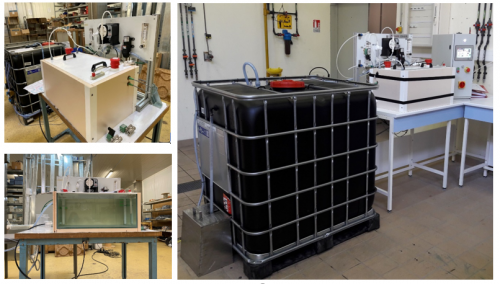

For the accelerated ageing campaign, two kinds of ageing are considered, the thermo-oxidative ageing and the immersion ageing, both planned to be performed at 40 and 80°C. The thermo-oxidative ageing in two ovens have already been launched on March 2021. The immersion ageing is planned to be carried out in two test loops which have been built inside of EDF polymers and composites laboratory during the first year (2021) of the project. The two test loops use reconstituted raw water and salt water respectively for the immersion ageing of materials. The immersion ageing using reconstituted raw water have been launched on February 2022.

The accelerated ageing tests will generate aged samples at different ageing times. Infrared spectroscopy characterizations are performed on these aged samples every month to follow their ageing evolution and to build a database of IR measurements for neoprene and HDPE.